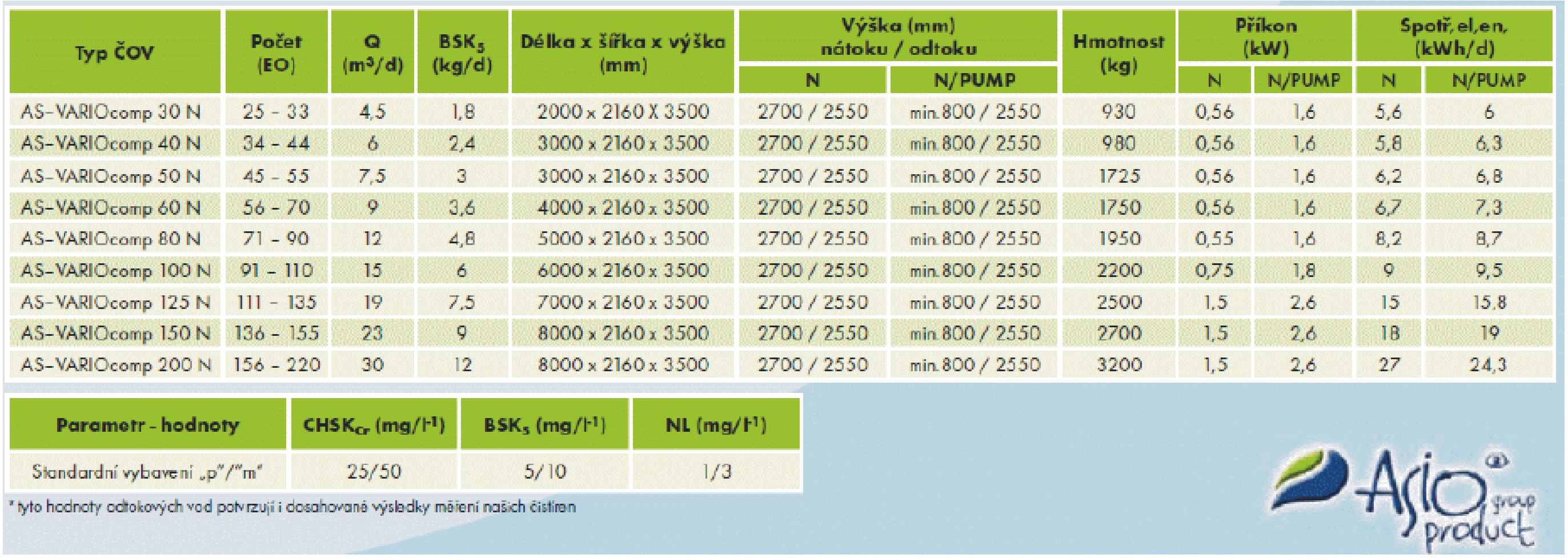

A line for 30–300 population equivalents. The wastewater treatment plant is designed for the treatment of sewage from permanently occupied buildings for 30 to 300 population equivalents. The treatment plant is equipped with membrane technology, which removes most viruses and bacteria from treated water. The treated water exhibits a quality comparable to that of rainwater and can be used both for irrigation and as service water for the household.

DESCRIPTION OF THE TECHNOLOGY

The WWTP consists of an all-plastic tank divided with partitions into individual technological compartments. The tank contains a micro-filtration module comprised of an air distribution system and aeration elements, membrane, and mammoth pump. The tank is covered with a removable lid.

Wastewater flows to the settlement compartment of the inlet part of the WWTP, where mechanical, floating and sedimentable solids are removed, which are further subject to anaerobic degradation (hydrolysis). From the settlement compartment, mechanically pre-treated water flows into the activation compartment through an overflow, where a membrane section containing a micro-filtration module is located.

The activation compartment is used for the biological treatment of wastewater and micro-filtration through membranes. In its bottom part, this compartment is equipped with a fine-bubble aeration system that is used for the aeration of the tank as well as for cleaning the membranes, into which air is forced by a blower. An advantage of this design is that the treatment plant works in the range between the minimal and maximal operation levels, which provides an accumulation capacity throughout the entire space of the treatment plant, which is designed to store wastewater and to ensure an even outflow of wastewater from the treatment plant.

The activated mixture from the activation compartment is filtered through membranes with the pore diameter of 0.03 µm under pressure and drained into the outlet.

Should the module fail (pump defect, clogging of the module) the activated mixture from the activation compartment will flow to the vertical secondary settlement tank, where sludge is hydraulically exhausted from its bottom, back to the activation compartment, and in the case of sludge of a high density, then into the sludge compartment as well (as in a conventional WWTP). Treated water is then drained via a submerged pipe to the outlet trough.

Excess sludge is exhausted with the use of a manually operated mammoth pump to the settlement and sludge compartments.

DRAINED WATER QUALITY

On the condition that the water entering the WWTP corresponds to municipal sewage, as regards its composition and character, in accordance with ČSN 75 6402 “Wastewater treatment plants up to 500 population equivalents", the AS-VARIOcomp ULTRA WWTPs are normally able to achieve the outflow values specified in the table that follows.

The membrane technology represents a combination of the conventional activation process and a very efficient separation of the solid (activated sludge, AS) and liquid phase (treated wastewater).

Mechanically pre-treated wastewater (WW) is aerated, biologically treated, and subsequently all solids that are smaller than the size of the membrane pores (0.03 µm) are removed from it by means of the membrane. Thus, particles that are smaller than the dimension of the pores only penetrate from the filtered media to the filtrate (permeate).

Selected references

AS-VARIOcomp 50N/ULTRA, location: Ostrava (DINO PARK), CZ

AS-VARIOcomp 150N/ULTRA, location: Loket (McDonald´s), CZ

AS-VARIOcomp 200N/ULTRA, location: Tošovice (HEIpark), CZ