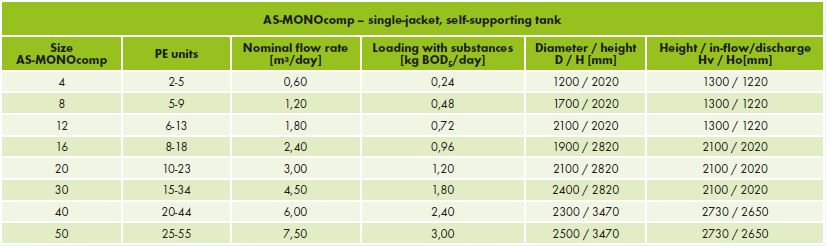

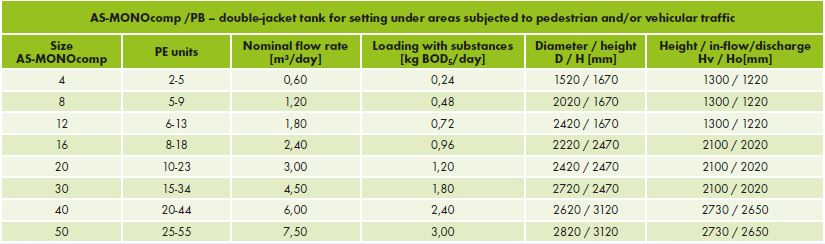

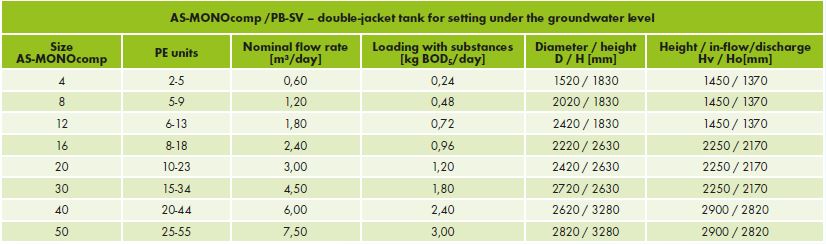

The wastewater treatment plant AS-MONOcomp is intended for purification of municipal sewage. This SBR-type wastewater treatment plant (further as WWTP), with its purification process, is equipped with a blower controlled electronically by a microprocessor control unit, and optionally fitted with phosphorus-precipitating equipment and/or UV lamp for the sensitisation at the cleaned water discharge. The certified product is easily installed and attended; the issues with its surplus sludge disposal are properly handled. In the WWTP the sludge is disposed by an integrated dewatering device, which provides for withdrawal of excessive sludge to a separated sludge section and it stabilisation with a possibility of consequent composting (4 to 16 PE) or removal and carrying away from an external sludge tank (20 to 50 PE).

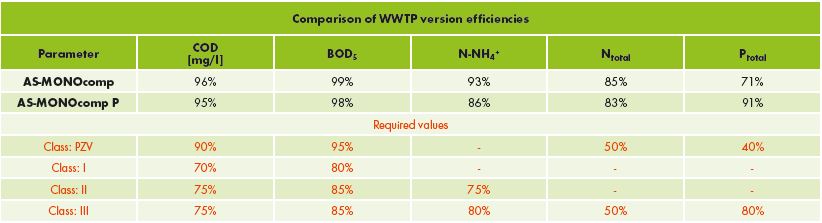

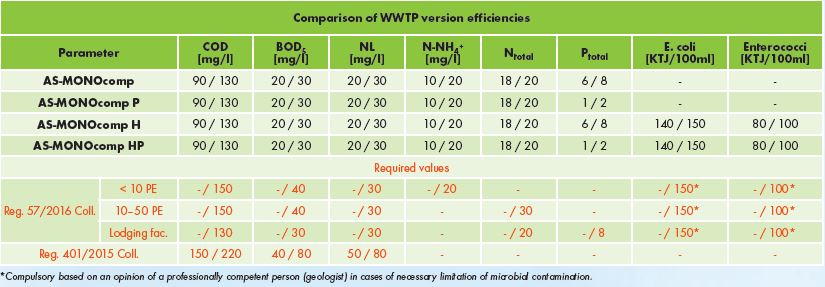

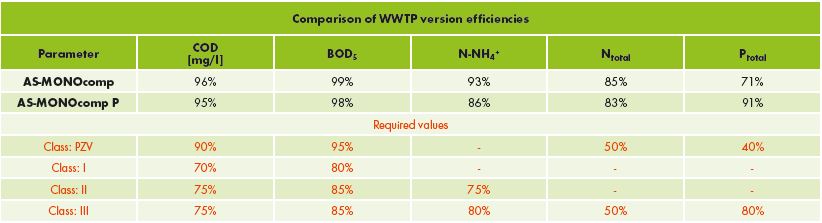

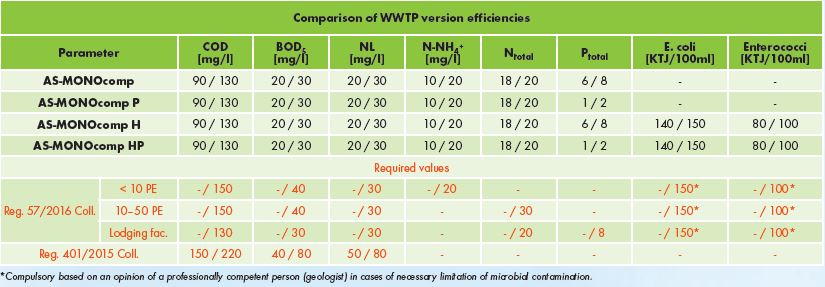

This WWTP is available in several versions: for 2 to 50 PE it meets the requirements of Class DČOV III, according to Regulation 401/2015 Coll., PZV Category, and the limits of microbial contamination according to Regulation 57/2016 Coll.

Advantages of the AS-MONOcomp treatment plant

-

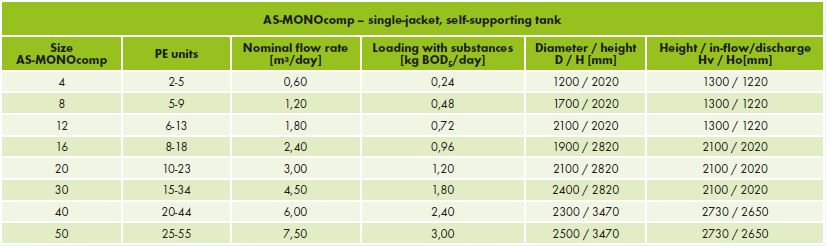

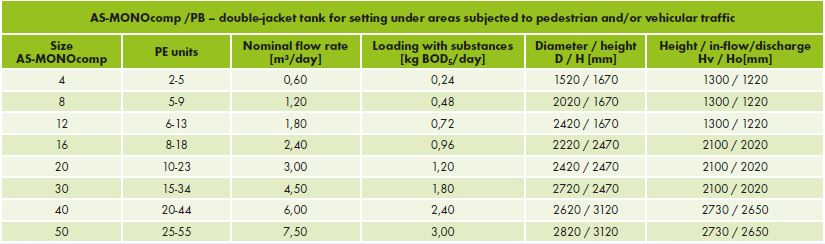

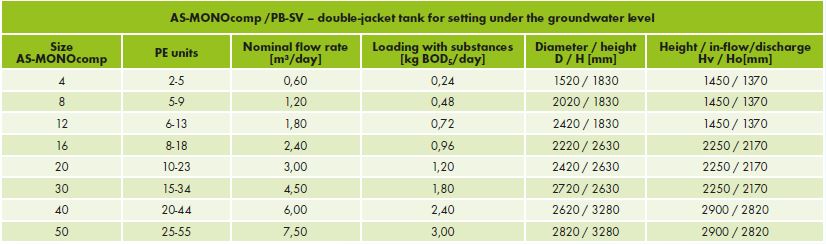

Reliable, well-proven tank structure available in several options

-

WWTP can be approved for discharge to underground and surface waters upon announcement

-

Simple technology with proven, high reliability and efficiency

-

Low-cost sludge disposal is solved

-

Available phosphorus-precipitating and/or sanitisation options

-

Possibility of using of cleaned water for irrigation purposes

-

Possibility of remote supervision over the plant

-

Entry stack, man-bearing cover, blower and control unit are included in the price

-

Advantageous price for the PZV-type WWTP approved on announcement

-

Low operating costs

-

Customer support and servicing available throughout the Czech Republic

AS-MONOcomp process description

Wastewater is brought over the feed basket to the feed section of the SBR reactor of the WWTP, where the inflowing water is steadied and partial sedimentation of mechanical impurities takes place. In the SBR, wastewater undergoes the purification process, where a controlled cleaning cycle is used during the day with alternating phases of aeration, sedimentation, flushing, discharge and sludging take place. During the aeration phase, the tank is filled and aerobic processes take place. Floating microorganisms are flocked to floccules, and remove by aerobic degradation organic contaminants and convert them into biomass. The sedimentation of floccules is supported by the interface created between the activated sludge and cleaned water. Flushing prevents undesirable withdrawal of insoluble materials into the discharge. Cleaned water is then withdrawn into the discharge trough. The surplus sludge that is produced in the WWTP is finally pumped to the de-watering equipment for its stabilisation and consequent disposal.

WWTP AS-MONOcomp – versions

WWTP AS-MONOcomp can be supplied in four versions according the requirements for cleaned water parameters:

A standard plant version without phosphorus-precipitation and sanitization of discharged cleaned water.

A standard plant version extended with the phosphorus-precipitation equipment, but without sanitization of discharged cleaned water.

A standard plant version extended with the equipment for sanitization of discharged cleaned water, but without the phosphorus-precipitation equipment.

A standard plant version extended with the phosphorus-precipitation equipment and sanitization of discharged cleaned water.

Installation of the WWTP

The plant installation is quite easy. The tank is settled into an excavation, on a foundation concrete slab, and then it is connected to the sewer system as well as interconnected (with hoses laid in protective sleeves) to the control unit (and the blower); the latter is connected to power supply (230 V/AC).

Samples taken from the WWTP

If the plant is to be utilized in the framework of the standard water-management administration procedure, then it is recommended to construct downstream the plant an inspection and sampling point, or the REVO shaft, for taking the samples. Then it will be possible to take the samples individually.

Additional possibilities

-

Monitoring of the plant using the AS-GSM device, which enables to monitor the plant operations and inform the owner about operational conditions and out-of-order events, if any.

-

For cases of long-term underloading of the treatment plant with wastewater, there is an artificial-feeding device available.

-

A standalone pillar or a wall-hung cabinet accommodating the blower and the control unit can be provided for the WWTP.