AS-GW/AQUALOOP – that smart water loop from ASIO

Even though it is not obvious at first glance, the used water handling directly influences quality and quantity of drinking water (influence to the contamination of underground water) as well as the quality of surface waters. The least contamination of surface waters is caused by the used water, which is never discharged.

Recycling of water in household, but particularly in hotels, commercial centres, and office blocks is widely used in many countries. There you can encounter various certifications of buildings according to internationally recognised standards - LEED, BREAM, SBToolCZ.

This paper is focused to two installations of the AS-GW/AQUALOOP technology. One for the commercial use, while the other for a family house.

Installation of AS-GW/AQUALOOP in a family house – Kelmis, Belgium

The family house is situated on the Belgian side of the Aachen/Kelmis border crossing. It is a typical family house, which provides - after its reconstruction - permanent accommodation for four inhabitants. There is a cellar under the house (used as a plantroom), while another storey and an attic are fit for habitation. Photovoltaic panels are fitted to the roof.

Fig. 1 – Family house in Kelmis, (Belgium)

Water in the house

The water system in the house is interestingly designed. Rainwater from the room and a small shed is brought down to an 8 m3 retention tank. The tank is located underground in a park in front of the house. The AQUALOOP built-in structure for rainwater filtration is placed inside the tank. Once filtered, the rainwater is pumped into a 300-litre aboveground tank (see Fig. 2, left side) placed in the plantroom.

This water is then pumped, over an UV lamp, by the AS-RAINMASTER Favorit unit (see Fig. 2, top right) to the water distribution system. It is possible to connect to the AS-RAINMASTER Favorit unit, over its free discharge also drinking water (the unit meets the EN 1818 Standard), for cases of rainwater shortage. An interesting point is that this water is preferably used for showering and washing and not for flushing of toilets. The water sanitisation is guaranteed by the MBR filtration and the UV lamp. Greywater from showers and bathtub is brought also to the plantroom.

Fig. 2 – Plantroom – placement of tanks

Fig. 2 – Plantroom – placement of tanks

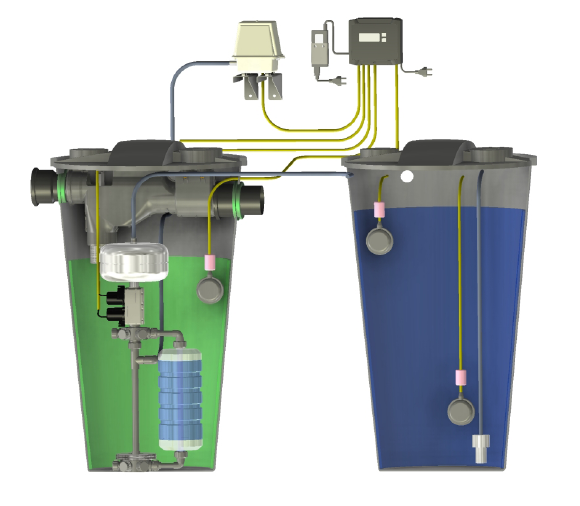

Two 300-litre tanks for greywater are situated there (see Fig. 2, bottom left). The first tank is designed as an accumulation/bio-reactor. The AS-GW/AQUALOOP built-in structure is inside this tank. After its mechanical pre-treatment, the water flows into the tank, where it is biologically cleaned, and - in exactly preset intervals – drawn off over membranes to the second tank - the reservoir.

A great advantage of the AS-GW/AQUALOOP system is the possibility of back-flushing of its membranes (up to the pressure of 3 bars). This design essentially lengthens the membrane service life and prevents dramatic drops in the flow rate because of clogging. The cleaned water is used for flushing of toilets and irrigation in the garden. Drinking water is used only for cooking and, in case of rainwater shortage, also for showering.

In addition, this connection makes possible to use both rainwater and greywater. For the sake of comparison, it can be noted that the annual consumption of drinking water in this household is approx. 10 m 3 .

Fig. 3 – AS-GW/AQUALOOP 6

Fig. 3 – AS-GW/AQUALOOP 6

Installation of AS-GW/AQUALOOP in the hotel complex

The installation of the AS-GW/AQUALOOP in-built system for the Galant**** hotel in Mikulov is one of the first commercial utilisation of this technology in the Czech Republic. Pre-treated greywater and rainwater is accumulated in the existing reservoir (about 10 m 3 ). The AS-GW/AQUALOOP in-built system is placed in the reservoir. After the biological treatment, water is filtered through membranes (six pieces) and then pumped to the existing reservoir placed in the building’s cellar. From this reservoir, the utility water system is supplied and this water is then used for flushing of toilets.

Design parameters

|

Water quantity: |

3 m 3 per day |

|

|

Max. daily inlet |

5 m 3 per day |

|

|

Contamination |

Inlet |

Outlet |

|

BOD 5 COD-Cr Insoluble substances Ammonia nitrogen Total phosphorus Enterococci Salmonella Escheria coli Thermo-resistant coliform bacteria |

51.1 mg/l 248 mg/l 95.8 mg/l 0.182 mg/l 1.1 mg/l 0 CFU/ml negative 50 CFU/ml |

3.8 mg/l 25 mg/l < 2.0 mg/l < 0.04 mg/l 0.029 mg/l 0 CFU/ml negative 0 CFU/ml |

Technical parameters

- Max. quantity of treated water: 5 m 3 per day

- Plant absorbed power: 380 W

- Aeration: start/stop – 10/5 minutes

- Suction: 2×20 cycles (one cycle: 15 minutes)

- Backwash: 2×20 cycles (one cycle: 15 seconds)

- Daily power consumption: 4.4 kWh

- kWh/m 3 : 1.5

Greywater - calculations

Due to the fact that several projects for greyw ater utilisation are processed at present and, from the side of designers, some questions have been raised as regards the calculations of water production and consumption within the framework of the buildings connected with the design of greywater recycling equipment, we have decided to offer to them a tool. This tool is a very simple program (in Excel) processed on the basis of the relevant Czech Standard (ČSN 75 6780) and our experience – see http://www.asio.cz/cz/stanoveni-produkce-sede-vody .

Apart from this program, ASIO, spol. s r.o. offers also its assistance with the technical design preparations, concrete technology proposals and economic return assessment.

Next articles

ASIO CELEBRATES ITS 30TH ANNIVERSARY … a reason for retrospection and de-liberation as how to proceed in the future

In the turbulent waters of the nineties, a company emerged on the market that was founded as a grass root development.

Learn more …

13. 6. 2023

Polypropylene Pickling Tanks

It is a robust plastic structure, which is evidenced by the fact that the tank contains a solution of 20% acid at temperatures reaching even the level of 80 0C.

Learn more …

30. 4. 2023