Construction of the first wastewater treatment plant using the membrane technology in Bosnia and Herzegovina

The wastewater treatment plant has been designed for treatment of municipal wastewater from employee sanitary facilities. The average design quantity of wastewater is 66.52 m 3 per day. In the design, potential intensification of the wastewater capacity up to 100 m 3 per day in the future has been taken into account.

Principles of the wastewater treatment process

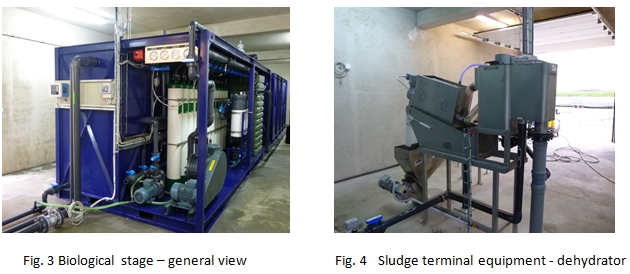

The wastewater stream coming from the employee sanitary facilities is brought over the complex sewer system to a pumping sump, from where it is pumped for mechanical pre-treatment. The mechanical pre-treatment stage consists of a rotary screen with one-millimetre pores. Mechanically pre-treated water then flows into a balancing reservoir, which is used for wastewater homogenisation and accumulation before it is pumped to the plant’s biological stage.

anjka local stream. An automatic system of membrane flushing (water and air are used) and equipment for CIP membrane cleaning are included into the process as well.

In regular intervals, surplus sludge is drawn off to a sludge tank, from where it is consequently pumped to a dehydrator for its de-watering.

Mgr. Zdeněk Hort

Next articles

ASIO CELEBRATES ITS 30TH ANNIVERSARY … a reason for retrospection and de-liberation as how to proceed in the future

In the turbulent waters of the nineties, a company emerged on the market that was founded as a grass root development.

Learn more …

13. 6. 2023

Polypropylene Pickling Tanks

It is a robust plastic structure, which is evidenced by the fact that the tank contains a solution of 20% acid at temperatures reaching even the level of 80 0C.

Learn more …

30. 4. 2023