Industrial wastewater treatment plant for the Borotice Slaughter-house supplied by the company of Petr Kratky

14. 11. 2013

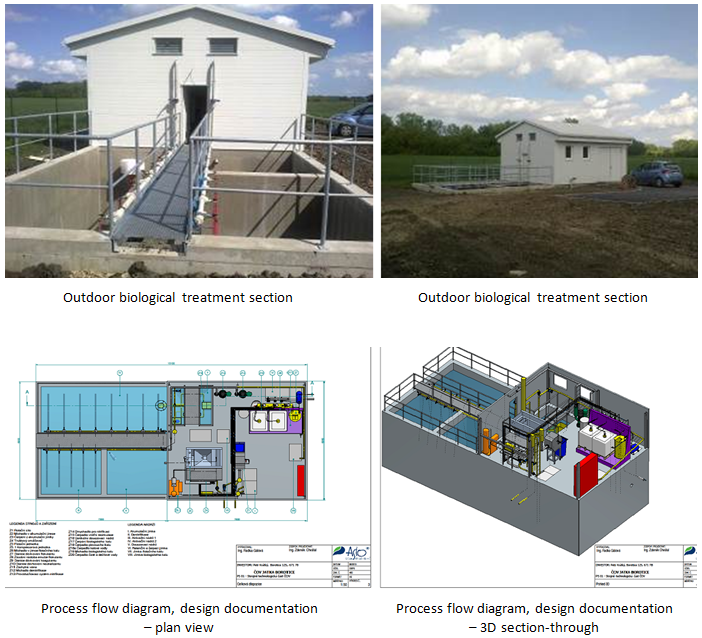

The project objective was the construction of a completely new mechanico-chemical process of wastewater pre-treatment together with a biological final treatment section and the outlet of cleaned water into the Jevišovka River water stream.

The subject matter of the implementation project is the treatment of process wastewater from cutting and meat-processing rooms.

In conversion to Population Equivalent (PE), the unit size corresponds to 1,488 PE. Wastewater daily quantities are about 38 m 3 per day.

Wastewater treatment principle – designed process flow diagram (PFD)

From the manufacturing units, the wastewater is brought over a preliminary cleaning process to the rotary screen inlet.

Free of mechanical impurities, the water stream flows off to an underground accumulation cesspool, which is stirred thoroughly. From the accumulation cesspool, the water stream is uniformly pumped into the flotation process including a chemical pre-treatment stage.

In the wastewater final treatment process, the biological section of the industrial WWTP is designed as an activation unit with upstream denitrification, consequent nitrification and sludge separation in a vertical settling tank.

The outlet of cleaned water is brought into a pumping and retention reservoir accumulating also rainwater drained from the area of the whole food-processing complex.

Ing. Martin Šrámek

Next articles

ASIO CELEBRATES ITS 30TH ANNIVERSARY … a reason for retrospection and de-liberation as how to proceed in the future

In the turbulent waters of the nineties, a company emerged on the market that was founded as a grass root development.

Learn more …

13. 6. 2023

Polypropylene Pickling Tanks

It is a robust plastic structure, which is evidenced by the fact that the tank contains a solution of 20% acid at temperatures reaching even the level of 80 0C.

Learn more …

30. 4. 2023