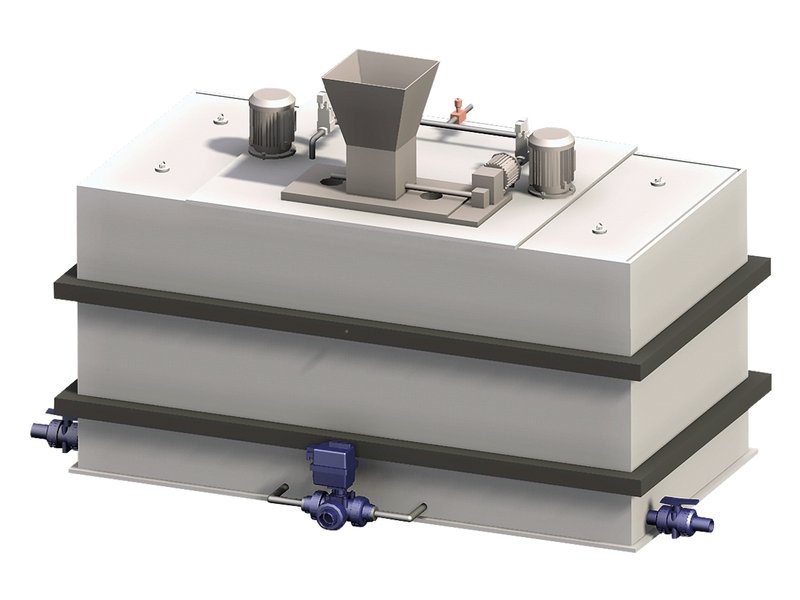

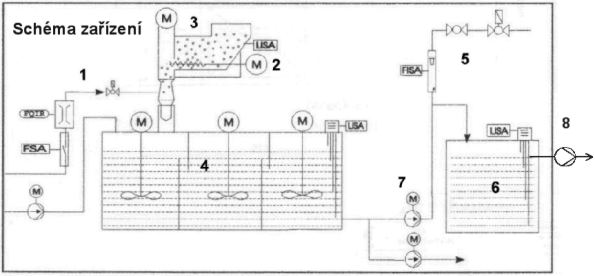

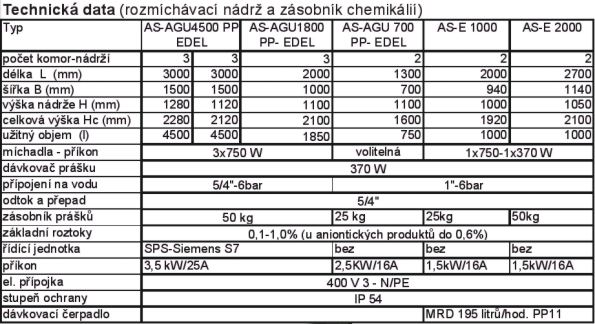

The equipment is designed for dissolution of powdered (granulated) chemicals. Its structure enables continuous operation and the precise adjustment of the concentration and agent dosing.

The equipment consists of a heated granulate hopper that prevents problems with granulate, a precise spiral dosing device, precise water dosing device, and a three-chamber mixing tank ensuring the production of a concentrated solution with a defined constant concentration. The equipment can be delivered in either a polypropylene (PP types) or stainless-steel (VA types) version.

Further, the equipment can be complemented with a reservoir and spiral conveyor of granulate, dilution unit ensuring further required dilution, and various types of mechanical mixers and mixing and storage tanks.

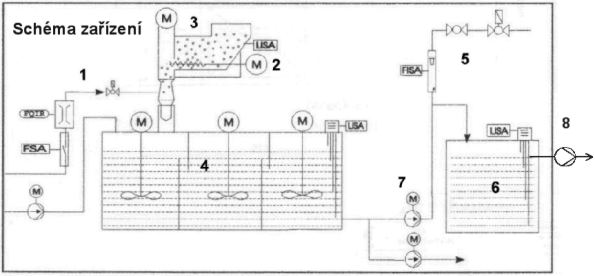

Legend:

1) Precise water dosing

2) Precise dosing of powdered or granulated chemical

3) Heated reservoir of chemicals

4) Mixing tank

5) Dilution unit

6) Storage tanks of the operation solution

7) Concentrate pumps

8) Dosing pumps

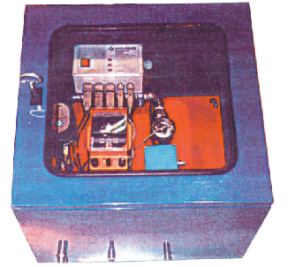

Dilution Unit AS – RJ

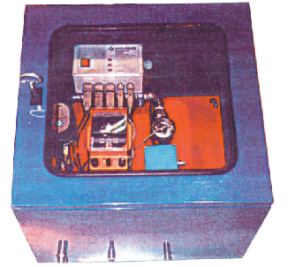

Example of the dilution unit

|

Example of the dilution unit

Legend:

1) Concentrate supply

2) Raw water supply

3) Mixer

4) Flow meter

|

Equipment description

The dilution unit is used for the continuous, precise dilution of concentrated solution. Concentrate supplied from the mixing tank or the liquid solution reservoir is mixed in the mechanical mixer with a precisely adjusted quantity of liquid. The equipment is usually designed as a panel with the dimensions of 800 x 1,000 mm, fitted with the required valves, installed on the mixing tank or on a wall. Alternatively, the panel may be closed in a cabin with a transparent front wall.

AS-S .../... mixer

Mixers are used for the mechanical mixing of two different types of liquid. The size of the mixer and material are determined individually on the basis of the chemicals used and flow quantities. Identification: AS-S diameter/length

|

Example of a mixer made of stainless steel designed for mixing

|