AS-VARIOcomp D (400 – 5,000 PE)

…

…

The wastewater treatment plant designated as the AS–VARIOcomp D is designed for towns and villages with 400 to 5,000 population equivalents (PE). In the design we applied our experience with previously supplied custom-made treatment plants and we put the priority on the stability of the treatment process, supported by low-load activation; high treatment efficiency, based on an innovative arrangement of the technology in the secondary settlement tank; and the minimization of operating costs that are mostly related to the final sludge stage.

The designed technology combines mechanical and biological processes of wastewater treatment, to optimize overall wastewater treatment efficiency in relation to energy demands. The common elements of the AS-VARIOcomp D line are the following technological units:

- Inlet pumping station

- Mechanical pre-treatment

- Low-load activation, designed with a front-end de-nitrification zone

- Square secondary settlement tank with vertical flow

- Device for the dehydration of excess sludge - “spiral dehydrator”

- Outlet flow meter

The sizing and calculation of the line are based on the specific production of wastewater, polluting substances, and load values, in accordance with the latest legislative requirements. The AS–VARIOcomp D WWTPs are designed for 1,000, 2,000, 3,000, 4,000 and 5,000 PE in the standard versions (400–800 PE are already normally supplied); however, any size between the standard types, or a larger WWTP, can be produced without any difficulty. The guaranteed quality parameters of the treatment plant outlet comply with the parameters required by Government Regulations No. 61/2003 Coll. and 229/2007 Coll., not only for pollution source sizes up to 2,000 PE, but also for categories exceeding 2,000 PE.

Design parameters| Specific pollution production at the inlet | |||||

| Parameter | BOD5 | COD | Solids | Solids total | P total |

| Unit | g / EO • day | ||||

| Value | 60 | 120 | 55 | 11 | 2,5 |

| Loading parameters of standard WWTP types | ||||||

| PE number | PE | 1000 | 2000 | 3000 | 4000 | 5000 |

| Q 24 | m 3 /d | 165 | 330 | 495 | 600 | 825 |

| Q h | m 3 /h | 19,9 | 38,0 | 57,0 | 76,0 | 87,5 |

| BOD5 | kg/d | 60 | 120 | 180 | 240 | 300 |

| COD | 120 | 240 | 360 | 480 | 600 | |

| Solids | 55 | 110 | 165 | 220 | 275 | |

| Solids total | 11 | 22 | 33 | 44 | 55 | |

| P total | 2,5 | 5 | 7,5 | 10 | 12,5 |

| Emission standards of wastewater pollution, in accordance with Govt. Reg. 61/2003 Coll. and 229/2007 Coll. | ||||||||||

| WWTP Category | COD | BOD5 | Solids | N-NH 4 + | P total | |||||

| p | m | p | m | p | m | Average | m | Average | m | |

| Up to 2,000 PE | 125 | 180 | 30 | 60 | 40 | 70 | 20 | 40 | - | - |

| 2,001 and greater PE | 120 | 170 | 25 | 50 | 30 | 60 | 15 | 30 | 3 | 8 |

– Where the p values for the COD, BOD5, and Solids parameters refer to acceptable concentrations

– Where the m values must not be exceeded

| Emission standards of wastewater pollution, in accordance with Gov’t. Reg. 61/2003 Coll. and 229/2007 Coll. | ||||||||||||||

| WWTP Category | COD | BOD5 | Solids | N-NH 4 + | N-NO 3 - | Solids total | P total | |||||||

| p | m | p | m | p | m | Average | m | Average | m | Average | m | Average | m | |

| 1000 PE | 80 | 120 | 15 | 25 | 20 | 35 | 5 | 12 | 25 | 35 | 35 | 45 | 2 | 6 |

| 2000 PE | 70 | 110 | 10 | 20 | 20 | 35 | 5 | 12 | 25 | 35 | 35 | 45 | 2 | 6 |

| 3000 PE | 70 | 100 | 10 | 20 | 15 | 30 | 4 | 10 | 20 | 30 | 30 | 40 | 2 | 6 |

| 4000 PE | 60 | 90 | 10 | 20 | 15 | 30 | 4 | 10 | 20 | 30 | 30 | 40 | 2 | 6 |

| 5000 PE | 60 | 90 | 10 | 20 | 15 | 30 | 4 | 10 | 20 | 30 | 30 | 40 | 2 | 6 |

In the case of extremely high requirements for outflow parameters, a design for the insertion of a membrane technology (MBR) can be prepared and submitted.

| Usually achieved parameters after precipitation and MBR | ||||||||||||||

| WWTP Category | COD | BOD5 | Solids | N-NH 4 + | N-NO 3 - | Solids total | P total | |||||||

| p | m | p | m | p | m | Average | m | Average | m | Average | m | Average | m | |

| 1000 – 5000 | 20 | 40 | 5 | 10 | 1 | 5 | 5 | 10 | 15 | 25 | 20 | 35 | 1,5 | 3 |

– MBR can be used as an optional modular extension of the AS–VARIOcomp D.

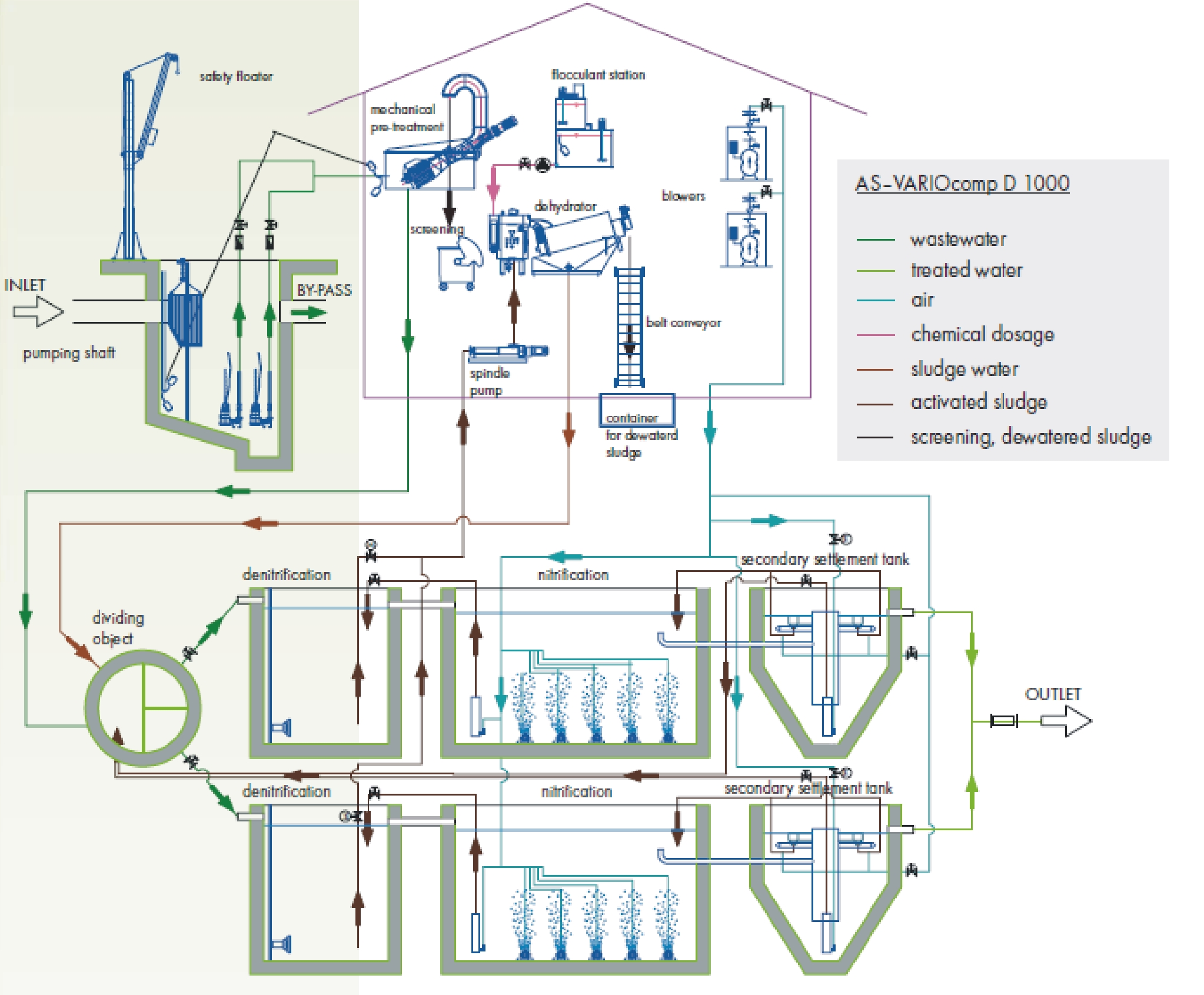

Description of the technology of the AS–VARIOcomp D

The first part of the machine’s technological unit is a circular pumping station. The station is produced in two types of different sizes, having a boundary at 2,500 PE. The pumping stations are equipped with a rough rack basket and a lifting device. For the pumping of wastewater for up to 1,400 PE, two pumps with alternating operation are used, while for over 1,400 PE there are three pumps with cyclic operation.

Mechanical pre-treatment is done with self-cleaning screw racks with machine scraping. Separated screenings are collected in a screening container. The manually scraped racks in the bypass represent a backup. Mechanically pre-treated water flows by virtue of gravity to the dividing structure before the biological part of the WWTP. In treatment plants where the reduction of the phosphorus content in drained wastewater is required, the precipitation of phosphorus by the dosing of precipitant in the stream of inflowing water, before the dividing structure, is proposed.

The activation part consists of nitrification and front-end de-nitrification. Internal recirculation is introduced between the tanks, which ensures the reduction of the outlet concentration of nitrate nitrogen. For treatment plants for under 2,000 PE, the internal recirculation is ensured by means of mammoth pumps; in larger plants internal recirculation pumps are employed. The de-nitrification tanks are fitted with low-speed submersible propeller mixers on the activation device. The tanks are also equipped with fine bubble aeration elements, to enable the aeration of the tank in the period when the temperature of wastewater is lower. The aeration elements are installed on supporting pipes in each tank. In the nitrification tank, fine bubble aeration elements are installed to ensure the supply of oxygen. Single-speed blowers act as the source of oxygen for the nitrification, and in the winter period also for the de-nitrification tanks.

The secondary settlement tanks are designed as two square tanks with a vertical flow. Water flows into the secondary settlement tank via a degasification zone and stilling cylinder. Return sludge is exhausted by means of a mammoth pump, and by standard pumps in larger WWTPs. An innovation is the extraction of treated water by means of a system of submerged collectors, combined with the automatic skimming of floating sludge and the possibility of simple adjustment of the level height. The above-stated combination ensures the minimization of leaks of un-dissolved substances, thus contributing to higher efficiency.

The sludge management

is designed so as to minimize operating costs. Excess activated sludge is pumped via the AS-PROchem D flocculation station directly to a spiral dehydrator that is able to condense sludge to 18 - 20% of dry matter, with minimal energy requirements. An advantage of this equipment is that it can work in a fully automatic operation. For illustration, we are "only" quoting the reaction of the investor to the first pilot unit put into actual operation more than a year ago:

We have been using the dehydrating equipment supplied by you - spiral dehydrator - for more than approx. 12 months. During this time period, the WWTP operation (2,500 PE) has yielded considerable savings amounting to about CZK 30,000 per month. The savings result from a reduction of the quantity of sludge transported from the WWTP.

During the installation and operation of the equipment, we were provided with 100% expert support by the supplier. During the period of use there has not been any defect or failure of the dehydration equipment working in the fully automatic mode. The operation of the dehydration equipment is simple and easy. The WWTP operators are very satisfied with it.

Ing. Jan Helikar – Mayor

Operation automation The control system of the treatment plants of the AS-VARIOcomp D line is fully automatic, incl. inflow pumping, the pumping of return and excess sludge, sludge extraction ,and synchronization with the operation of the final sludge stage (spiral dehydrator).

Automatic control of the entire system is ensured through:

Technological diagram of a 1,000 PE WWTP - AS-VARIOcomp 1000 D

|

Selection from the reference list

Project name

|

Place of implementation

|

Capacity

|

Optional modular technology extension

Besides the chemical precipitation of phosphorus and the membrane technology, the system may be extended with a rainwater holding tank, a cesspit, or by modifying the technological design to a system with regeneration, in the case of operational stability requirements or other structures.

Device for the chemical precipitation of phosphorus If the Ptotal limit needs to be met in a WWTP for under 2,000 PE, we are able to achieve these limits in all WWTPs by means of a device for the chemical precipitation of phosphorus.

Membrane technologies In the case of high outlet parameter requirements, a design with wastewater treatment by means of the membrane technology may be prepared and submitted. Mechanically pre-treated wastewater is biologically treated and then un-dissolved substances are removed from it by means of membranes. The size of the pores in the membranes is in the order of microns. Bacteria and most viruses will not penetrate into the filtrate (permeate). An advantage of water treated in this manner is that the drained water is hygienically treated and can be recycled or infiltrated.

What we have verified in practice is that microbiological indicators for a WWTP with membrane filtration achieve a quality enabling reuse, e.g., as service water (see the table below).

| Bacteriological analysis of water drained from MBR | |||

| Unit | Analysis 1 | Analysis 2 | |

| Escherichia coli | CFU in 100 ml | 0 | 0 |

| Coliform bacteria | CFU in 1 ml | 0 | 5 |

| Intestinal enterococci | CFU in 1ml | 0 | 0 |

| Determination of clostridia | CFU in 50 ml | 0 | 0 |

| Cultivable bacteria at 22° C | CFU in 1 ml | 530 | 370 |

| Cultivable bacteria at 37° C | CFU in 1 ml | 295 | 530 |

Regeneration tank to meet requirements for operation stability It can be designed to increase resistance to toxic inflow and to compensate for uneven substance loading.

SFT FILTER for cost savings To improve the energy balance of the plant, and to reduce tank volume requirements and aeration costs, a multifunctional unit (SFT FILTER) able to thicken or drain sludge can be designed in certain cases. The SFT FILTER is a compact unit designed for the mechanical separation of un-dissolved substances and their thickening. Current models are delivered with an output of 10 to 180 l/s, i.e., 36 to 648 m3/h. A fabric with openings from 0.1 mm to 1 mm is used as a sieve, which enables the optimization of solid substance removal together with the shift setting.

Operating costs

These consist of the direct costs of the electricity consumed by the machines and equipment, personnel costs for the operation and maintenance personnel of the WWTP, and possibly for the use or processing of excess sludge from the WWTP; and costs for the removal and disposal of screenings from the rack basket of the pumping station and mechanical pre-treatment, the purchase of chemicals for sludge dewatering and phosphorus precipitation, and the water consumed for the spraying of dehydrator lamellas and dissolution of the flocculant solution.

| Operation costs | |||||||

| PE | Total WWTP area (m 2 ) | El. power input | Water consumption | Coagulant consumption | Flocculant consumption | ||

| kWh | KW/d | kWh/m 3 | m 3 /d | kg/d | kg/d | ||

| 1000 | 270 | 20,5 | 139,0 | 0,84 | 0,94 | 0,00 | 0,54 |

| 2000 | 355 | 39,8 | 475,8 | 1,44 | 1,32 | 78,68 | 0,99 |

| 3000 | 450 | 53,0 | 653,8 | 1,32 | 2,02 | 118,02 | 1,48 |

| 4000 | 535 | 55,5 | 688,2 | 1,04 | 2,32 | 157,36 | 1,98 |

| 5000 | 615 | 67,6 | 833,3 | 1,01 | 2,81 | 196,71 | 2,47 |

Note: The total WWTP area means the built-up area of the tanks and the operation structure

WWTP operators

For up to 3,000 PE, one operator with specialized training is required for four hours a day; for over 3,000 PE, one operator with specialized training is required.

We offer the provision of comprehensive services

With regard to our commitment to provide comprehensive services, we are able to deliver not only the complete technology, but also everything else you may encounter in the construction of the WWTP, i.e.:

Conclusion

The line of AS-VARIOcomp D municipal wastewater treatment plants has been designed on the basis of long-term experience, with the priority given to the stability of the treatment process, treatment efficiency, and operational economy. The basic version comprises all components necessary to meet legislative conditions, and for a modular extension you can use individual optional devices that are able to meet heightened requirements resulting from the needs of the water management authority, the investor, or the environmental conditions of the particular location.

ČOV 1800EO/ULTRA, location: Hostivice (EUFI s.r.o.), CZ

ČOV 1800EO, location: Odřišov, CZ

ČOV 1750EO, location: Otnice, CZ

ČOV 1060EO, location: Kunín-levobřežní (Commodum, spol. s r.o.), CZ

ČOV 750EO, location: Dolní Morava (hotel Klepáč), CZ

ČOV 700EO, location: Tušimice (Elektrárna Tušimice), CZ

ČOV 800EO, location: Libeř, CZ

ČOV 1700EO, location: Kolarovo (Nanjuk), BG

ČOV 1800EO, location: Bauska (Lielzeltini), LV

ČOV 5000EO, location: Ligatne, LV