AS-TOP WASH

La station de traitement des eaux usées WASH AS-TOP est une machine conçue pour le traitement et le nettoyage des eaux usées produites lors du lavage de véhicules…

La station de traitement des eaux usées WASH AS-TOP est une machine conçue pour le traitement et le nettoyage des eaux usées produites lors du lavage de véhicules…

The AS-TOP WASH wastewater treatment plant is machinery designed for the treatment and cleaning of wastewater produced during the washing of vehicles.

The AS-TOP WASH wastewater treatment plant is intended for continuous operation, which is controlled by level switches installed in an under-floor pump sump and in the re-treated water accumulation tank. If there is an insufficient quantity of water in the re-treated water accumulation tank, the pump of the underground pump sump, which pumps wastewater (hereinafter referred to as WW) to the treatment plant, is switched on, automatically activating the function of the WWTP. If re-treated water is required and there is no WW in the under-floor pump sump, pressurized water from the main is automatically filled into the re-treated water accumulation tank.

Re-treated water can be reused for washing vehicles or drained into the sewerage system if it is permitted in the local conditions.

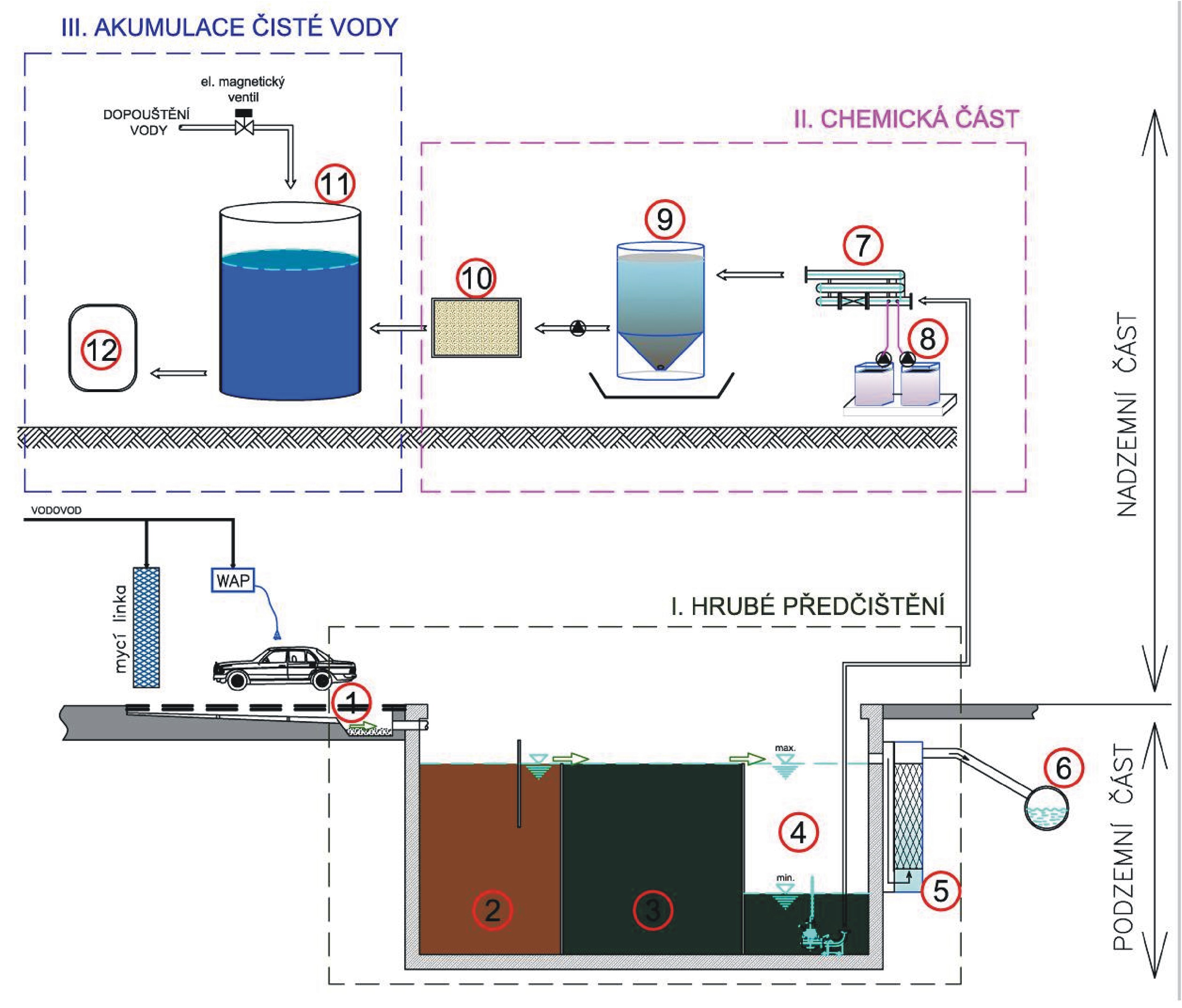

Wastewater from washing vehicles flows via a collection trough with gates (1) into the settlement tank (2,3) the last part of which consists of the pump sump (4). In the settlement tank, mechanical, floating, and sedimentable substances are largely removed from the wastewater. Light liquids are also separated here.

From the pump sump (4) wastewater is transferred with the use of a pump (submersible or suction) into the settlement reactor (9). Wastewater flows into the reactor via a mixing pipe (7) where WW is mixed with operation chemicals (8). Operation chemicals are dosed into the mixing pipe with the use of special dosing pumps that ensure the even dosing of chemicals to activate a coagulation - flocculation process in the mixing pipe. This causes the mutual binding of substances contained in the wastewater and subsequent agglomeration in flocs. These flocs settle in a cone on the reactor bottom, where they accumulate and are subsequently manually released into the settlement tank (2) at regular intervals.

Water without sediments and impurities is drained from the settlement reactor (9) into the accumulation tank of re-treated water (11). If necessary, the equipment may be supplemented with a final treatment filter (10) that re-purifies drained water after the reactor and is installed directly in the accumulation tank (11). Re-treated water from the accumulation tank (11) is utilized by means of an AT station (12).

If there in a sufficient quantity of re-treated water in the accumulation tank (11), wastewater is drained from the pump sump (4) by gravity into the sewerage system (6) – or optionally via a sorption filter (5).

If there is not enough re-treated water in the accumulation tank (11) and no wastewater is available from the pump sump (4), the accumulation tank (11) is automatically refilled by pressurized water from the main.

| AS-TOP WASH – Set | |||||||

| Parameters | Units | WASH 0.5 | WASH 1 | WASH 1.5 | WASH 2 | WASH 2.5 | WASH 3 |

| Maximum flow | mł / h | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 |

| Recommended flow | mł / h | 0.33 | 0.65 | 0.98 | 1.30 | 1.63 | 1.95 |

| Daily flow | mł / day | 1.5 | 3 | 4.5 | 6 | 7.5 | 9 |

| Dimensional requirements of the operation room | m | 3.1 x 1.3 | 3.7 x 1.7 | 4.1 x 2.1 | 4.3 x 2.3 | 4.8 x 2.5 | 5 x 2.6 |

| Installed power input | kW | 3.07* | 3.07* | 3.07* | 3.07* | 3.07* | 3.07* |

*incl. a self-suctioning pump and AT station

| Inflow into the WWTP | ||

| NES | mg/l | 800-1,500 |

| Solids | mg/l | 300-2,000 |

|

Drain from the WWTP |

||

| NES | mg/l | up to 5 |

| Solids | mg/l | up to 20 |