A device for indicating an oil and grease layer on the surface, for grease traps and separators of low-density liquids.

- The design is based on EN 858-1 and 2

- Monitoring selected levels of oil, sludge, and liquids

- Prevention of accidents

- Indicating the need of maintenance – cost savings

- Reduction of the need of supervision

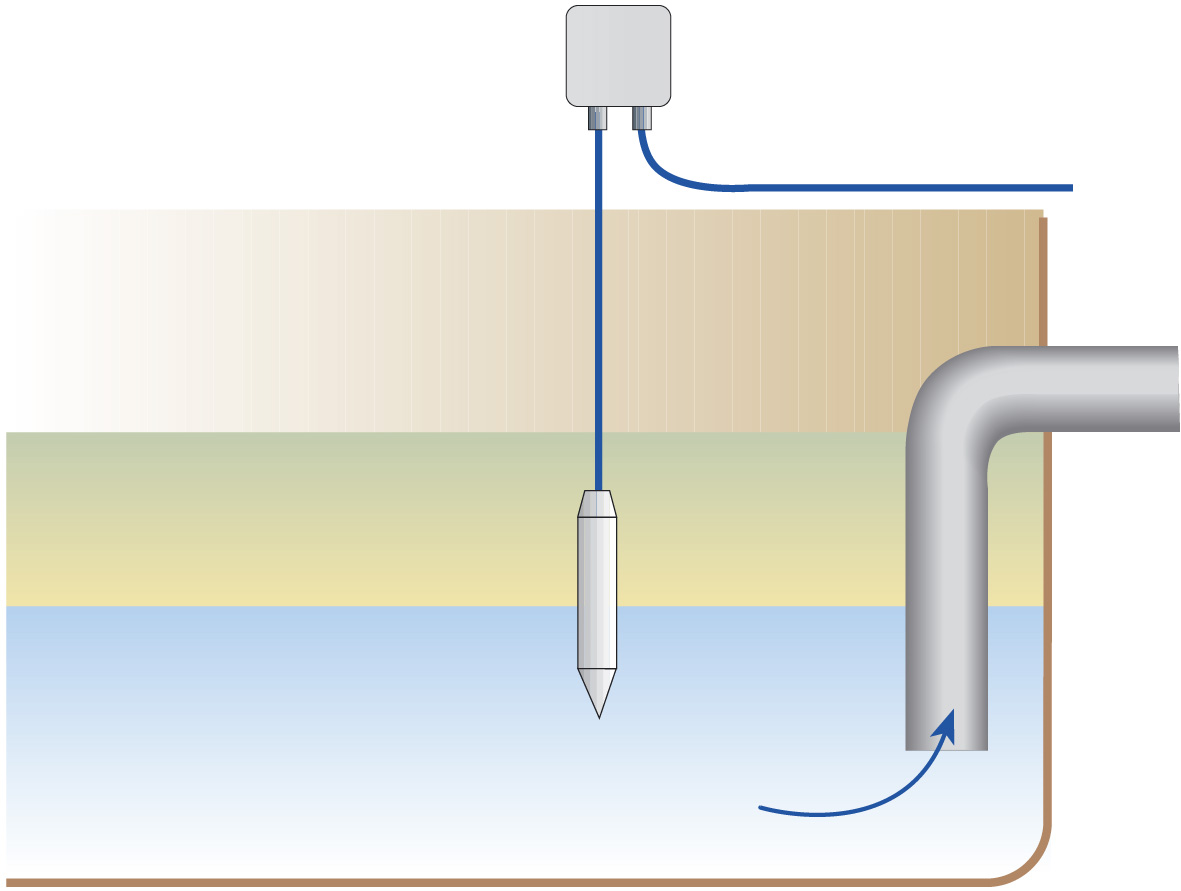

The monitoring devices check the level in separators of low-density liquids and grease traps and can indicate when captured oil and grease needs to be emptied, i.e., they indicate the need for waste disposal, to make it economical and environmentally safe.

The control unit and sensors have been verified in accordance with ATEX Directive No. 94/9/EC, for use in explosive environments.

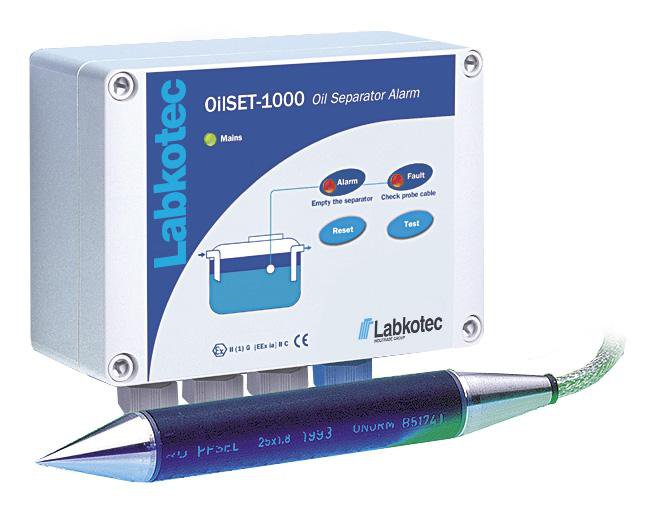

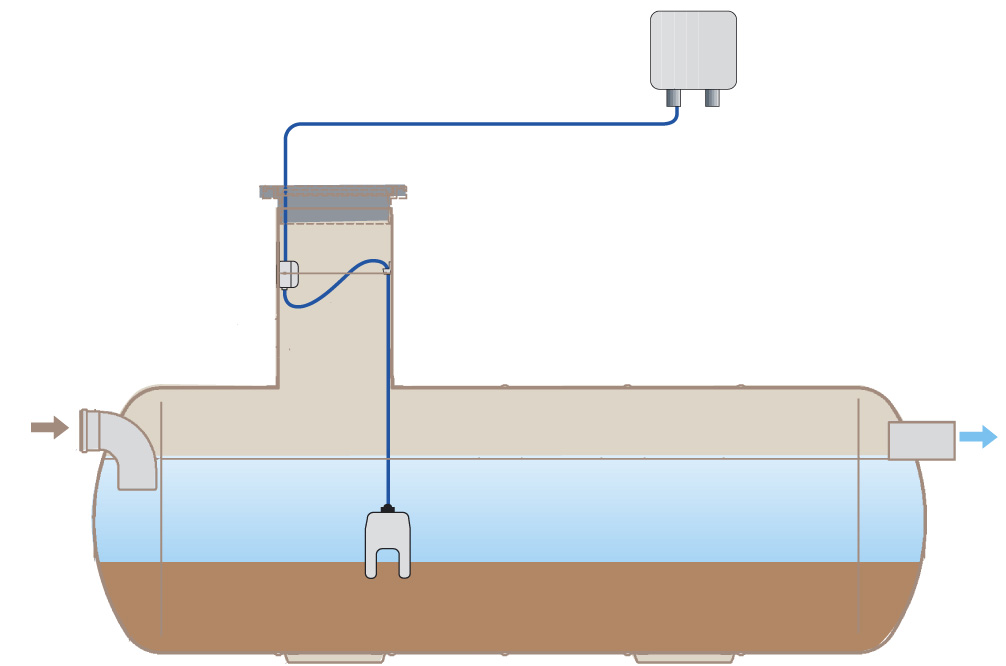

AS-LABKO OilSET-1000 Surface Oil Indication Set

The AS-LABKO OilSET 1000 device is designed for separators and traps and indicates the danger of leaks of captured oil substances/oils to the sewerage system.

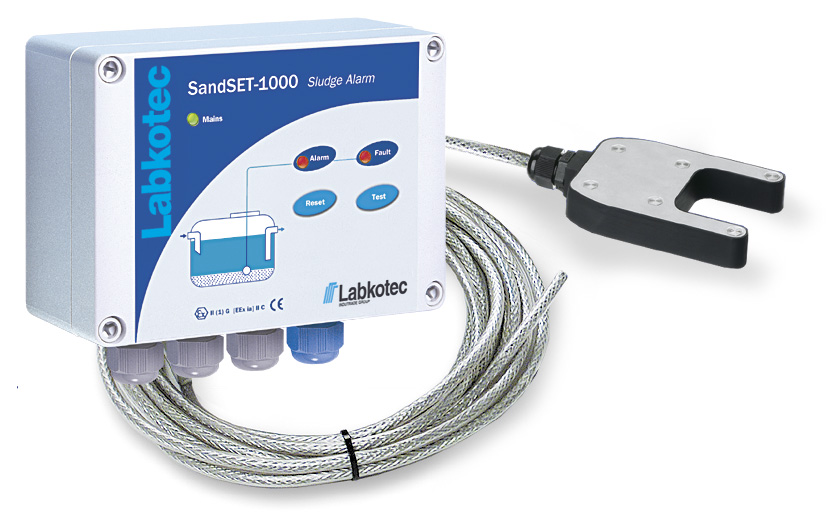

AS-LABKO SandSET- 1000 – Device for the Indication of the Sludge and Sand Levels

The AS-LABKO SandSET 1000 is a set that detect the thickness of the sand or sludge layer in a tank. The SET/S2 probe emits a signal if sludge or sand is between the ultrasonic sensors. The probe does not require any calibration or setting. You can just put it at a certain height.

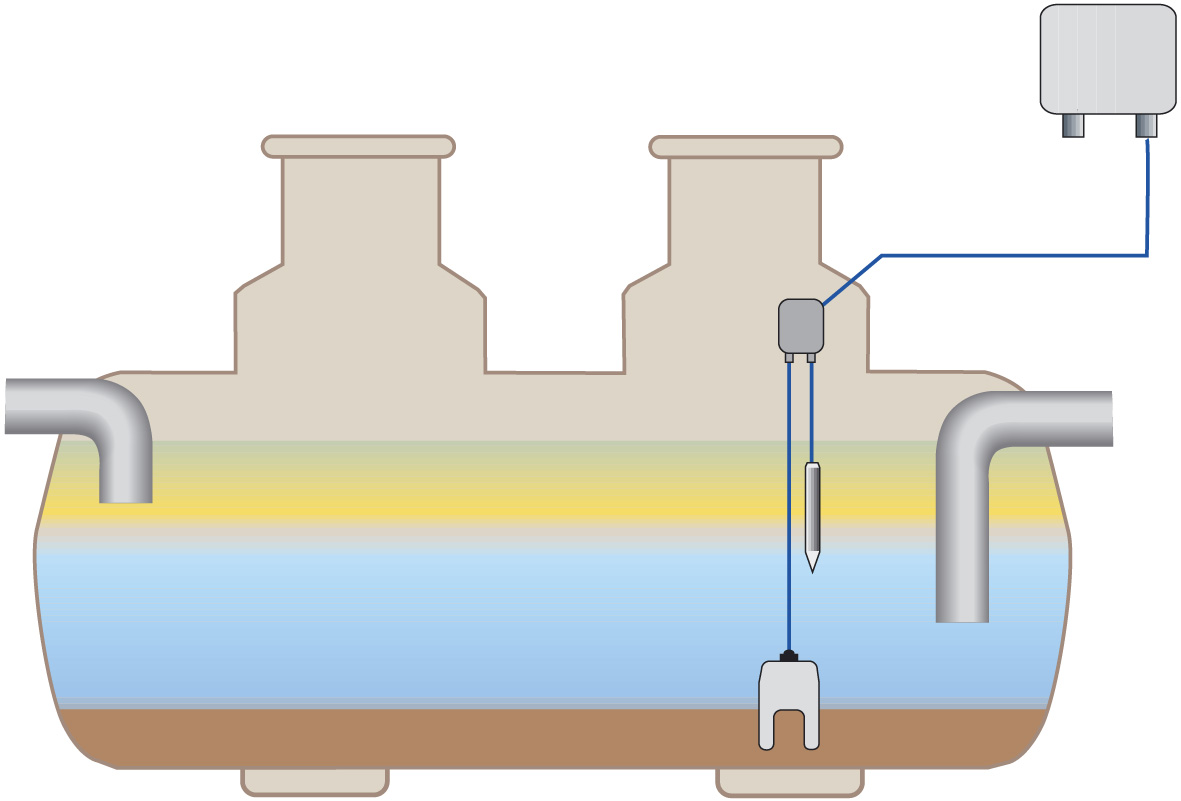

AAS-LABKO SET- 2000 Oil/Sludge – Indication Device with Two Sensors

The device is equipped with two sensors, one of which indicates the oil layer and the other the height of the sludge layer (i.e., that there is sludge between the ultrasonic sensors).

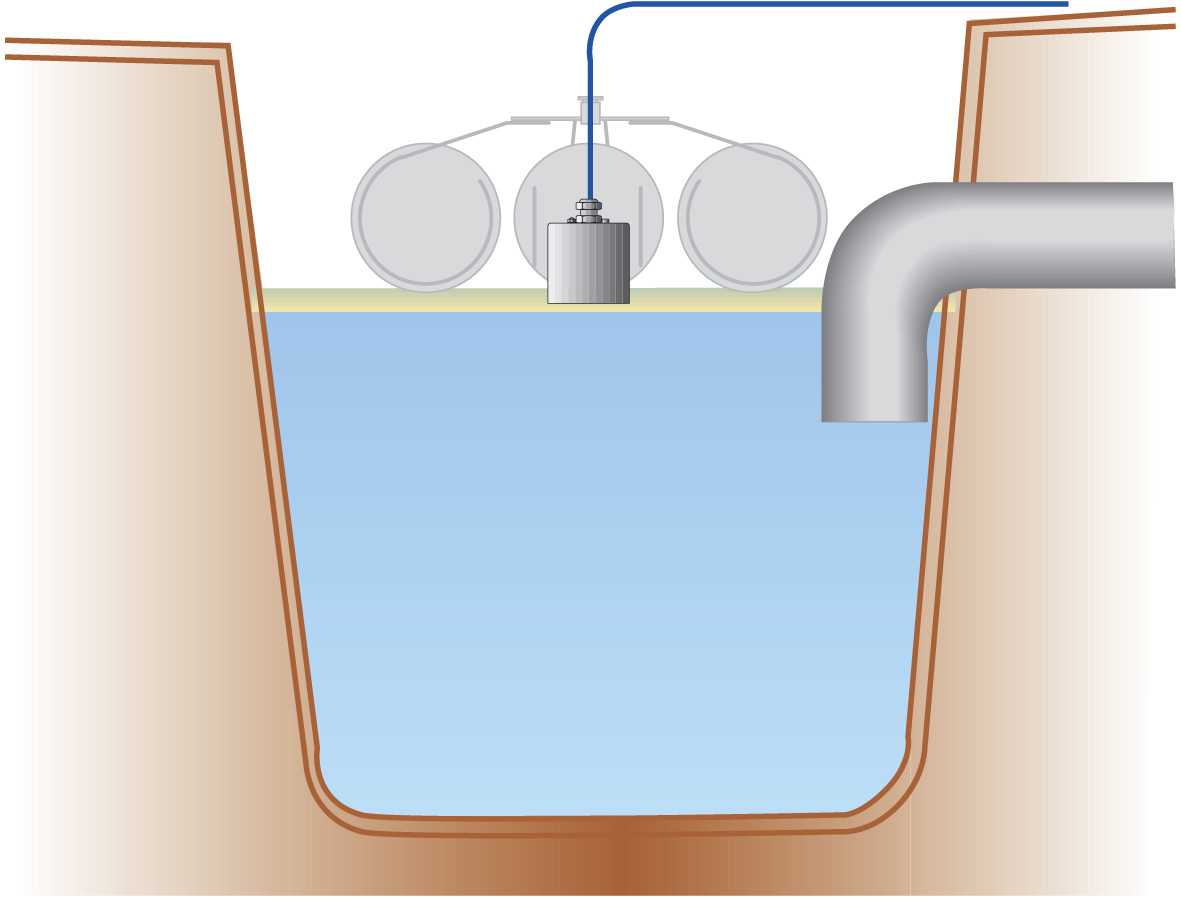

AS-LABKO SET/OSK2 - Sensor for Installation in Tanks

The sensor indicates an oil layer on the surface of a pumping shaft or tank.

AS-LABKO SolarSET – Solar Power Units

The unit indicates an oil layer on the surface in a separator in places with no power supply. In the case of a failure status, the unit sends an SMS message to the user’s mobile phone. The SolarSET contains an OilSET 1000 12VDC failure reporting sensor, a Labcom 12VDC communication unit, a battery, and a solar panel.