Can we help you?

Do you wish to receive a not-binding offer?

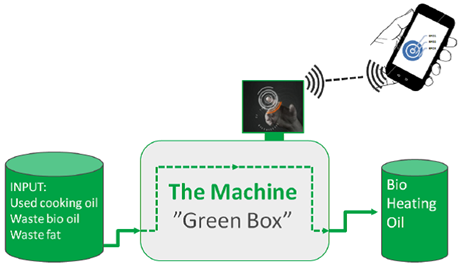

The BioHeatingOil project is ultimately developing a robust and cost-effective automated processing technology, a “Green Box”, for production of bio heating oil - using waste sources in form of fat & grease from the food production industry and grease traps as raw material.

![]()

Project BioHeatingOil of the 7th Framework Programme was launched in December 2013 and will be solved in the next two years in the framework of Research for benefits of small and medium enterprises grants, which means research and development for small and medium enterprises. “Development of an automated processing method, a “Green Box”, for production of bio heating oil from waste sources” with acronym BioHeatingOil is a research project aimed at production of “Green Box”, a technology for fuel oil production. The project will ultimately develop an automated processing method for production of bio heating oil - using waste sources as raw material. Waste sources suitable for the “Green Box” will be both fat & grease from the food production industry and fat & grease from grease traps, which are currently not utilized for bio oil production and instead disposed of at a cost. The first step in the creation of the "Green Box" will be to develop and build a filtration and cleaning prototype unit for bio fuel and oils. Subsequently, connecting other automated units enabling production of bio heating oil.

GREEN CUBE MANAGEMENT AS is a coordinator in this project who has experiences with fuel oils production and market strategies. Research on chemical principles is provided by Poland partner INSTYTUT CIEZKIEJ SYNTEZY ORGANICZNEJ BLACHOWNIA, whereas control system is prepared by Italian company LABOR S.R.L. Contribution of TEKNOLOGISK INSTITUTT AS TI, Norwegian technological institute, is designing and assembling the “Green Box”, prototype composed of three technological steps. It is apparent from type of the project, that big companies provide research for small and medium enterprises (SMEs), who will use the results for future production of technologies. There are three SMEs in the project: ASIO, spol. s r.o. provides valuable input in regards to product specifications for design, integration and testing, MALTHE WINJE AUTOMASJON AS is a designer of the process measurement and control system, Filtersystem Scandinavia AB is supplier of dewatering and filtration device.

The BioHeatingOil project is ultimately developing a robust and cost-effective automated processing technology, a “Green Box”, for production of bio heating oil - using waste sources in form of fat & grease from the food production industry and grease traps as raw material. In current State of the art (SoA) methods which use fat & grease as a raw material, quality of the raw material input to the production determines the quality of the end product. This is most often inconvenient, as the user requirement for the bio oil often differs from the production results. In addition, current SoA methods cannot handle waste from grease traps as an input media in their process as waste from grease traps is so varied in quality and hence difficult to process. This waste is therefore disposed of, at a cost. The “Green Box” will improve SoA and have market advantages by first providing an upgrading/ filtration unit, and ultimately an automated factory producing end product with pre-determined quality aside the production of bio oil from fat & grease waste.

Figure: Inputs and outputs of “Green Box” technology

The Green Box concept has also additional advantage in the form of environmental conservation. As the use of bio oil instead of fossil fuel reduces CO2 emission, and wastes are the input media for the production of bio oil by the “Green Box”, the process we develop will have a great sustainability factor. Other bio oil production processes compete with the food production industry as these processes require input media which can also be used as food, for example maize and canola oil.

The development includes identification and use of existing methods for analysis and parameter adjustment, and combine them with a control system. This results in reliable process automation.

Benefits for ASIO are know-how of Green Box technology, together with new knowledge of chemical processes and broadened experiences in material engineering, product specifications and process control.